Mechanical Testing Laboratory

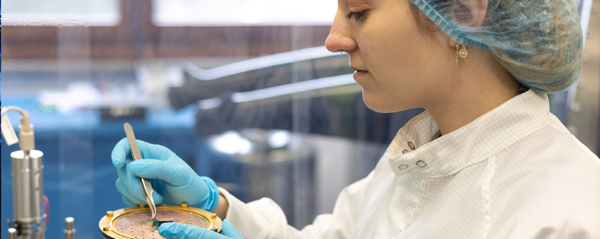

The mechanical testing laboratory specializes in determining the strength, hardness, and fatigue life of a wide variety of materials and components. Using high-precision tensile, compression, and bending test machines, hardness testers, and supporting measurement equipment, we deliver reliable results for design, quality assurance, and research.

- Hardness testers (Emco Test DV30G5, Qness Q10A+).

- Universal testing machines (Zwick Z250) up to 250 kN, optionally with high-temperature furnace up to 900 °C.

- Hydropuls test systems (Instron 8802, 8803, 8854; Schenk PS100) with inductive heating, vacuum chamber, temperature ranges from -150 °C to 900 °C, and high-precision laser extensometers.

- Resonance testing machines (Russenberger Testronic & Mikrotron-20) with high-temperature furnaces and temperature chambers.

- DCPD/ACPD measurement systems (Matelect + in-house design) for in-situ crack length measurements.

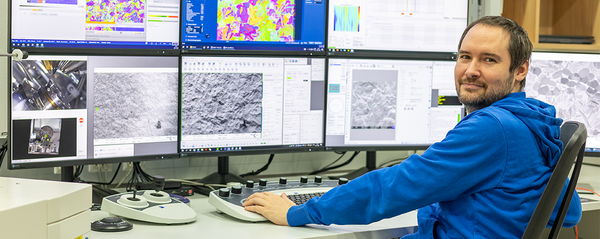

- Optical 3D deformation measurement system (ARAMIS) for precise motion and shape analysis.

👉 Comprehensive materials and component testing – from static tests to dynamic high-load and high-temperature experiments.