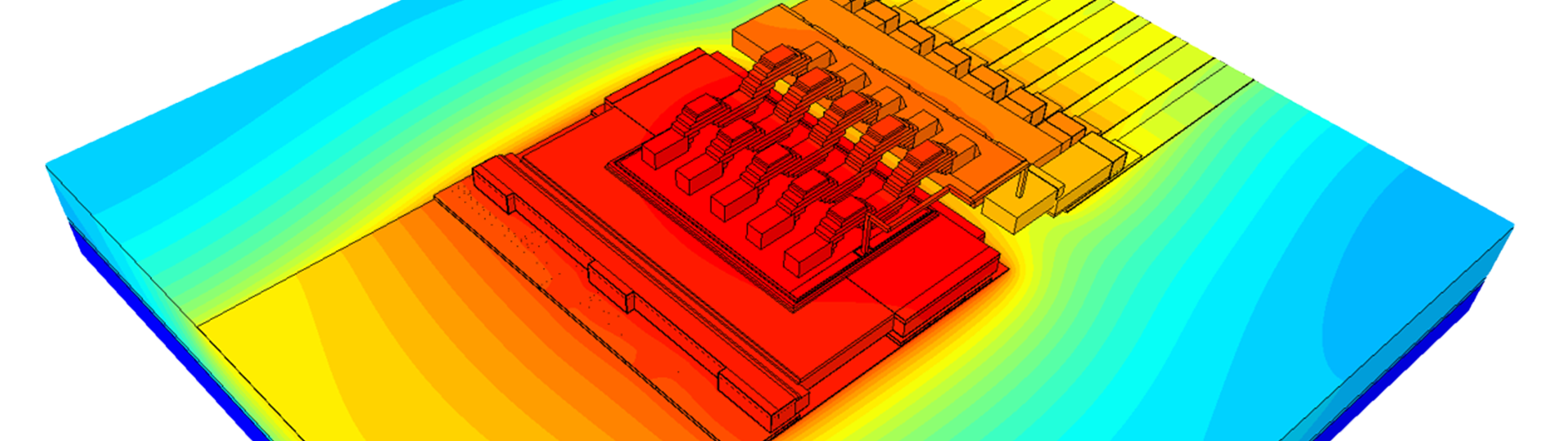

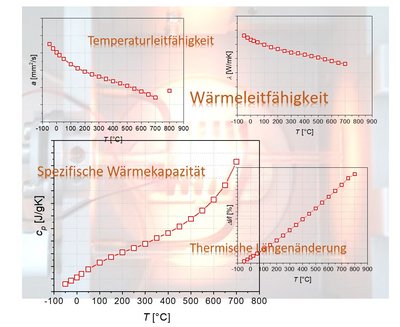

Determination of Thermophysical Properties

We determine the fundamental thermophysical properties of metallic and ceramic materials and their composites.

Our focus & expertise

- Determination of thermal diffusivity (–60 °C to 1200 °C) according to EN 821-2 (1997)

- Measurement of thermal expansion of solids (–150 °C to 1200 °C) according to DIN 51 045-1 (2005)

- Measurement of specific heat capacity (–150 °C to 1100 °C) according to EN 821-3 (2005)*

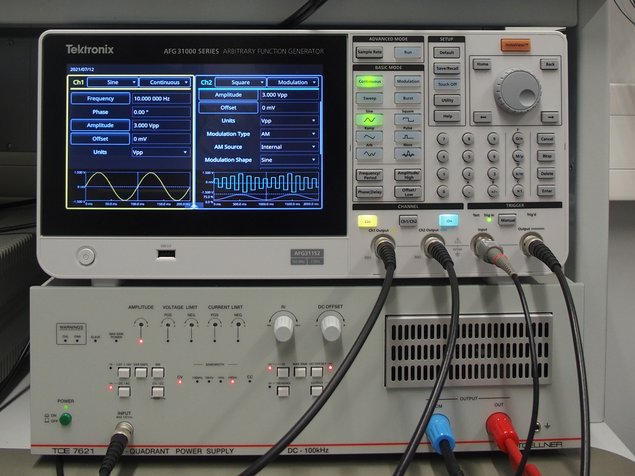

- Measurement of dynamic Young’s modulus (20 °C to 900 °C) according to EN 820-5 (2009)*

- Calculation of temperature-dependent thermal conductivity

- Measurement of electrical resistance/conductivity (20 °C up to the melting point of metallic samples)*

*In cooperation with the Austrian Foundry Institute (ÖGI)