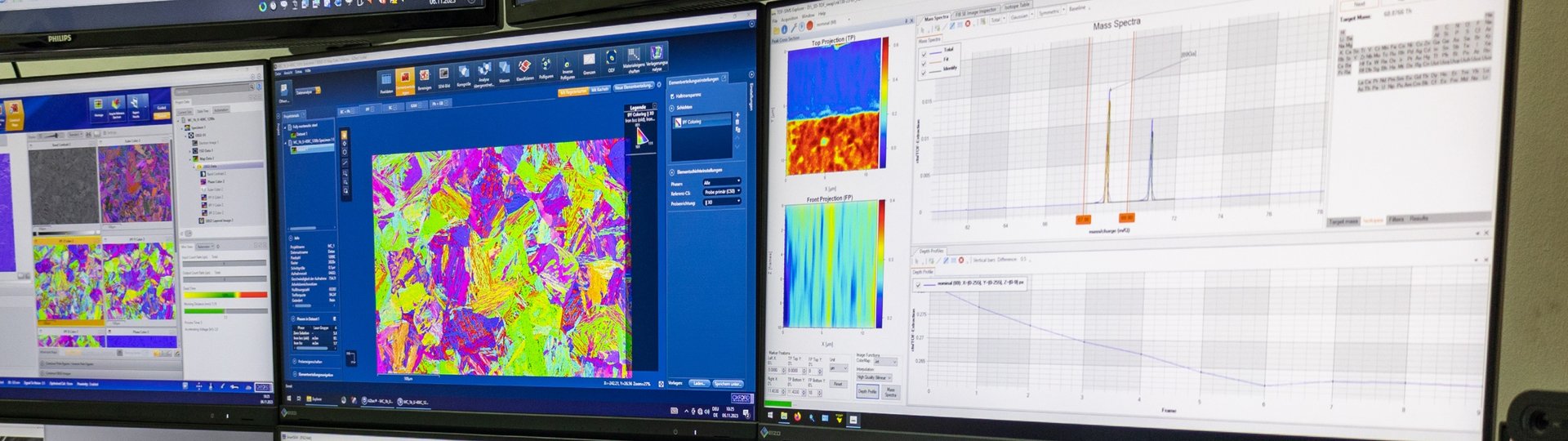

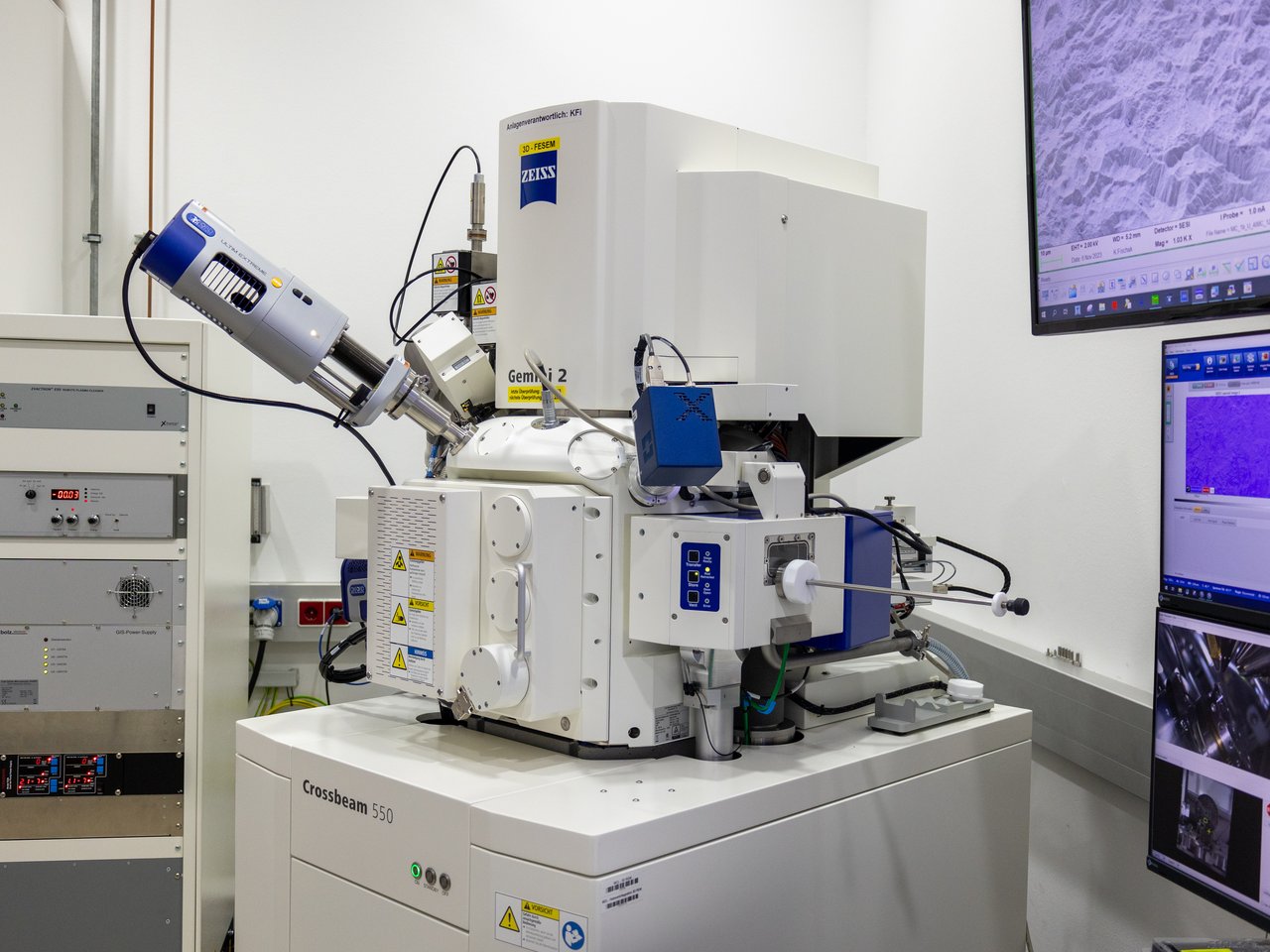

(Local) Chemical Analysis in the Electron Microscope

Methods

- EDX (Energy Dispersive X-ray Spectroscopy)

Lateral resolution down to 50 nm; windowless detectors for light elements.

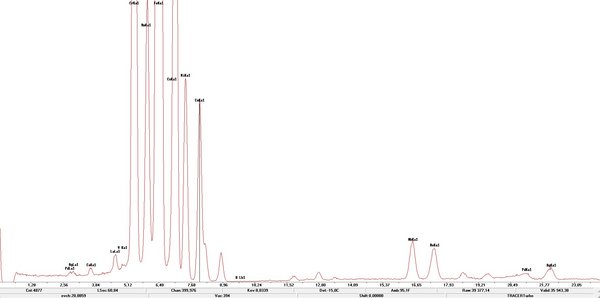

Fast qualitative and quantitative elemental analysis, spot analyses, and elemental mapping. - WDX (Wavelength Dispersive X-ray Spectroscopy)

Highest resolution and detection limits, precise quantification. - FIB-SIMS (Focused Ion Beam – Secondary Ion Mass Spectrometry)

Depth profiles, trace elements, isotope-specific analysis, 3D chemical mapping. - X-ray Fluorescence Analysis (XRF)

Low-damage, larger analysis volumes, elemental mapping down to trace levels.

Fields of application

Phase characterization and precipitate analysis

- Identification of carbide, nitride, and intermetallic precipitates

- (e.g. Cr carbides in stainless steels, Al-Mg-Si precipitates in Al alloys)

- Analysis of precipitate size, distribution, and chemistry

- Detection of undesired phases (σ-phase, Laves phase, Widmanstätten structures)

Particle, inclusion, and cleanliness analysis

- Chemical assessment of impurities such as non-metallic inclusions

(MnS, various oxides like Al₂O₃, SiO₂) - Automated particle size and distribution analysis

- Evaluation of steel cleanliness in line with standards (e.g. DIN/ASTM)

- Investigation of foreign particles in steelmaking, casting, and rolling processes

Identification of spallation, wear debris, and abrasion particles

Local microstructure and microstructural analysis

- Chemical analysis of individual microstructural constituents (heterogeneous materials, e.g. hardmetals/cemented carbides)

- Determination of segregations and microsegregations (e.g. Cr, Mo, Nb)

- Correlative analysis of microstructure vs. chemical composition

Identification of local corrosion initiators (MnS, intermetallic particles, foreign particles)

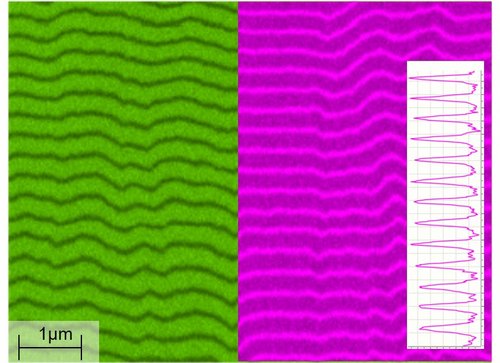

Coating properties and layer structure

- Analysis of multilayer systems (electroplated coatings, PVD, CVD, thermal spray coatings)

- Determination of layer thicknesses, diffusion zones, and composition gradients

- Detection of elemental enrichments or depleted regions (e.g. Cr-depleted areas)

- Investigation of passive layers, oxides, and corrosion products

Surface modification

- Chemical evaluation of nitrided, carbonitrided, and borided layers

- Analysis of coating adhesion, interfaces, and delamination

- Investigation of local hardness gradients via elemental distributions (C, N diffusion)

Depth profiling & nanoscale analysis (FIB-SIMS)

- Sub-micron depth profiles of coatings, diffusion layers, etc.

- Detection of trace and light elements (e.g. H, Li, B, N)

- Analysis of local contamination in the ppm range

- Investigation of hydrogen embrittlement (H mapping)