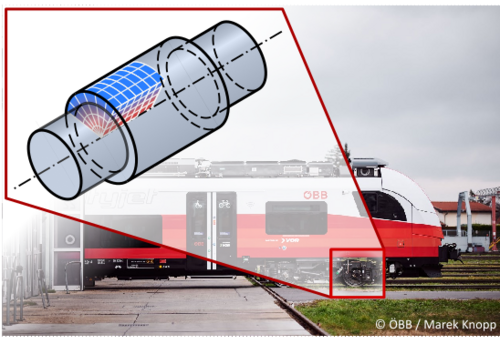

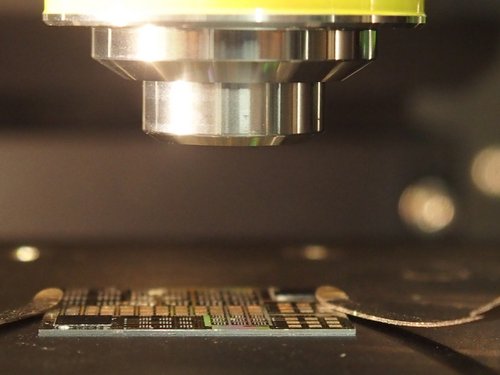

X-ray Residual Stress Analysis (Lab & Mobile)

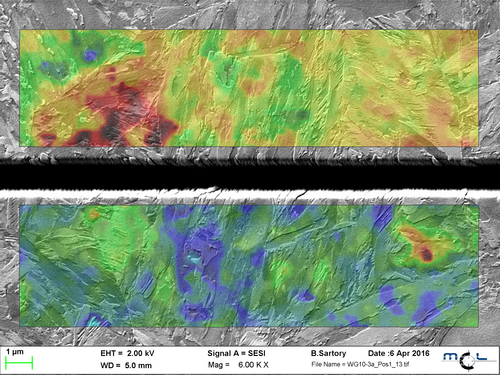

X-ray determination of residual stresses, stress distributions, and depth profiles on components in the lab or directly at the customer’s site

Residual stress development in coating/substrate systems under changing temperatures

Determination of residual stress relaxation at elevated temperatures up to 900 °C