Hardness Testing

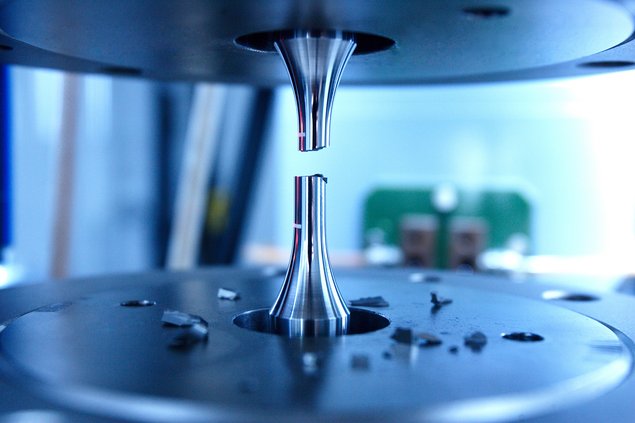

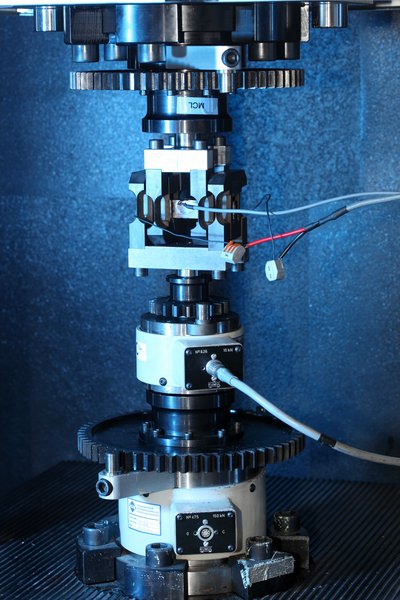

We offer comprehensive hardness testing using all common methods – from macroscopic measurements to nanoindentation.

Available hardness methods

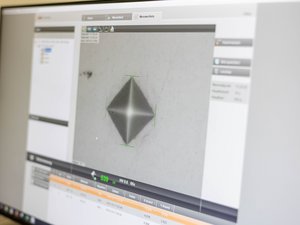

- Vickers hardness (HV) – EN ISO 6507-1

- Brinell hardness (HB) – EN ISO 6506-1

- Rockwell hardness (HRC) – EN ISO 6508-1

- Knoop hardness (HK)*

- Martens hardness (HM) / instrumented indentation (nanoindentation)*

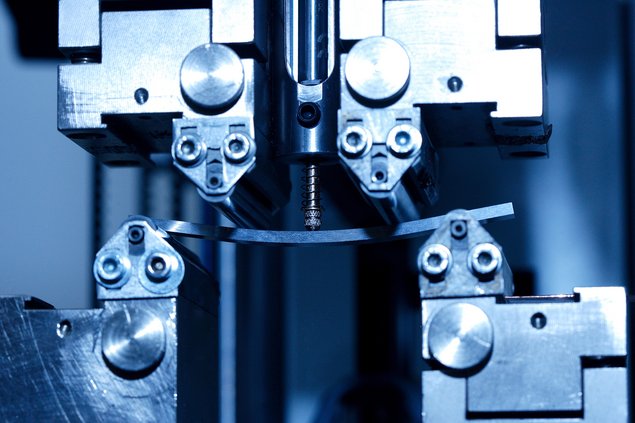

Testing services

- Core hardness measurements

- Hardness profiles or hardness mapping (e.g. after case hardening, nitriding, surface hardening)

- Depth profiles for coatings and transition zones

- Small samples / cross-sections

- Testing according to DIN EN ISO and ASTM standards

- Evaluation including documentation and test report

Typical applications

- Metallic materials (steels, non-ferrous metals, alloys)

- Coatings and thin films

- Ceramics and composite materials

- Heat-treated components

- Welded joints

*Outsourced to MCL-approved cooperation partners