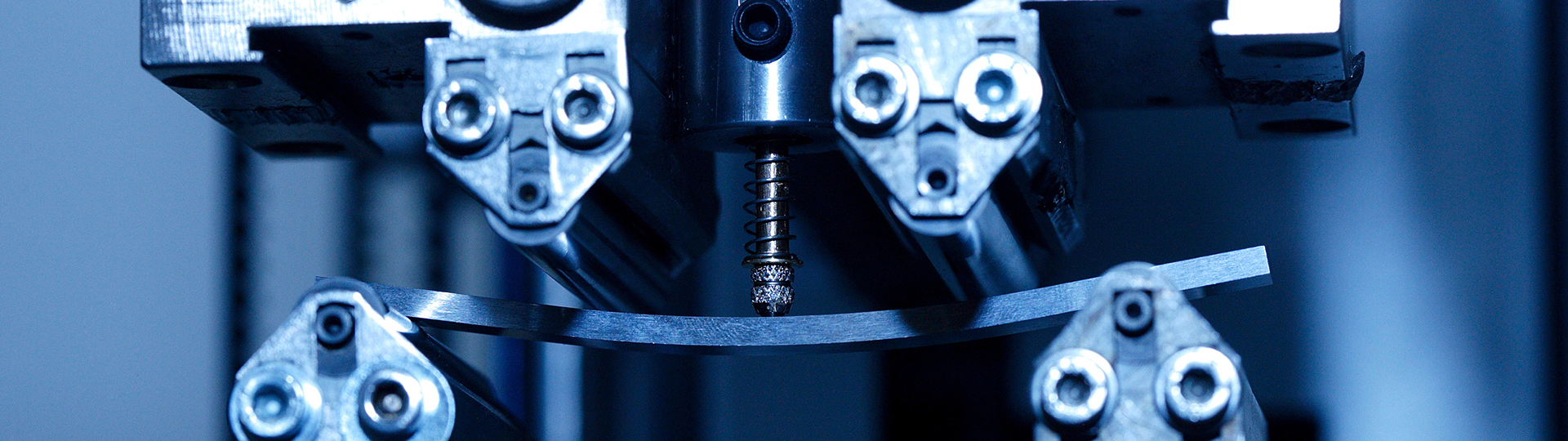

Material testing in accordance with ÖNORM EN 13262 – Wheelsets and bogies

We conduct tests on wheels for railway applications in accordance with ÖNORM EN 13262, which specifies the product requirements for wheelsets and bogies. The standard defines requirements for materials, mechanical properties, and manufacturing quality in order to ensure safety and reliability in railway operations.

Our testing services include:

- Chemical analyses: Ensuring that the composition of the wheel set materials complies with standards.

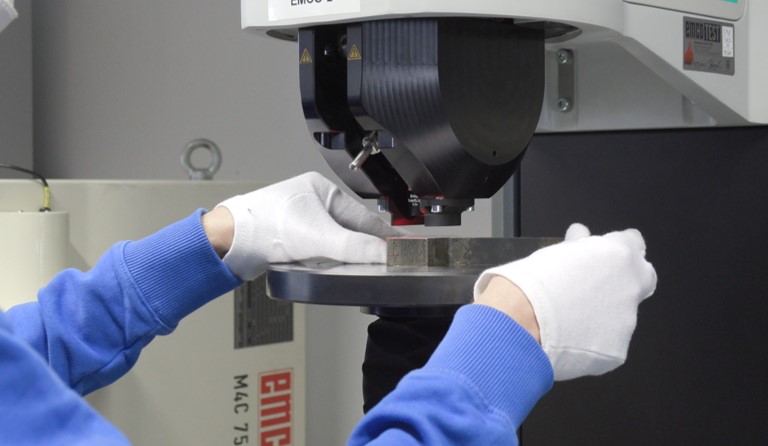

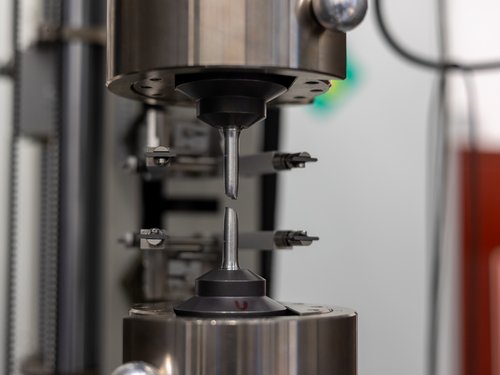

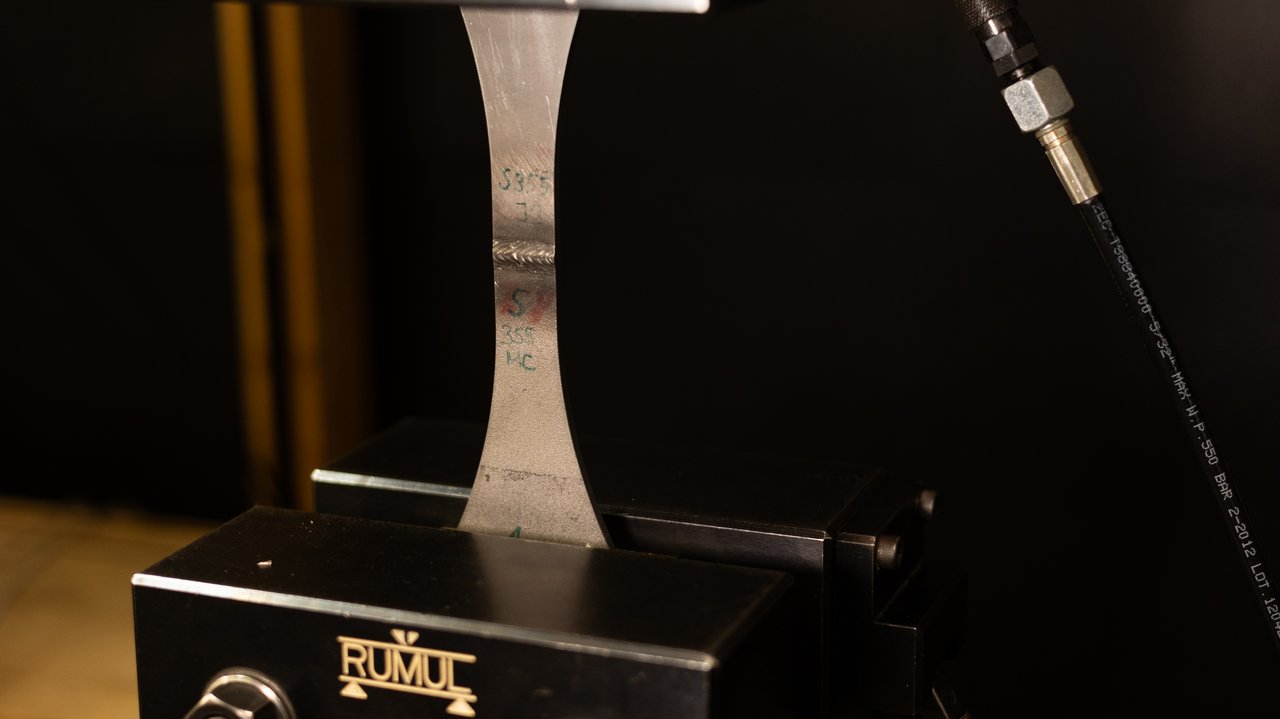

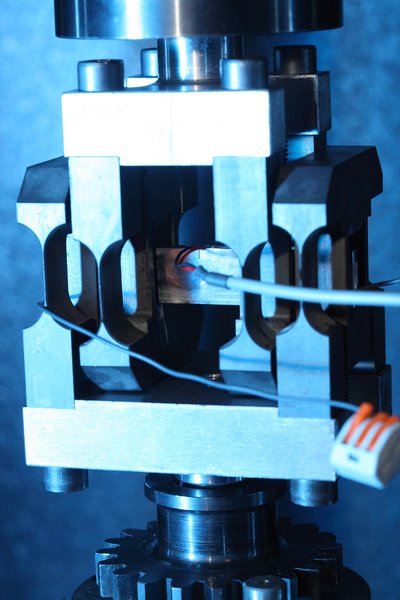

- Mechanical tests: Tensile and notch impact bending tests, fatigue strength tests, fracture toughness properties of the wheel rim, and hardness tests to evaluate heat treatment.

- Microstructure and macrostructure inspection: Inspection of grain structure, purity analyses.

- Residual stress measurements

- Surface properties (roughness)

- Proof of conformity: Documented compliance with all requirements of ÖNORM EN 13262 for safe wheelsets and durable bogies