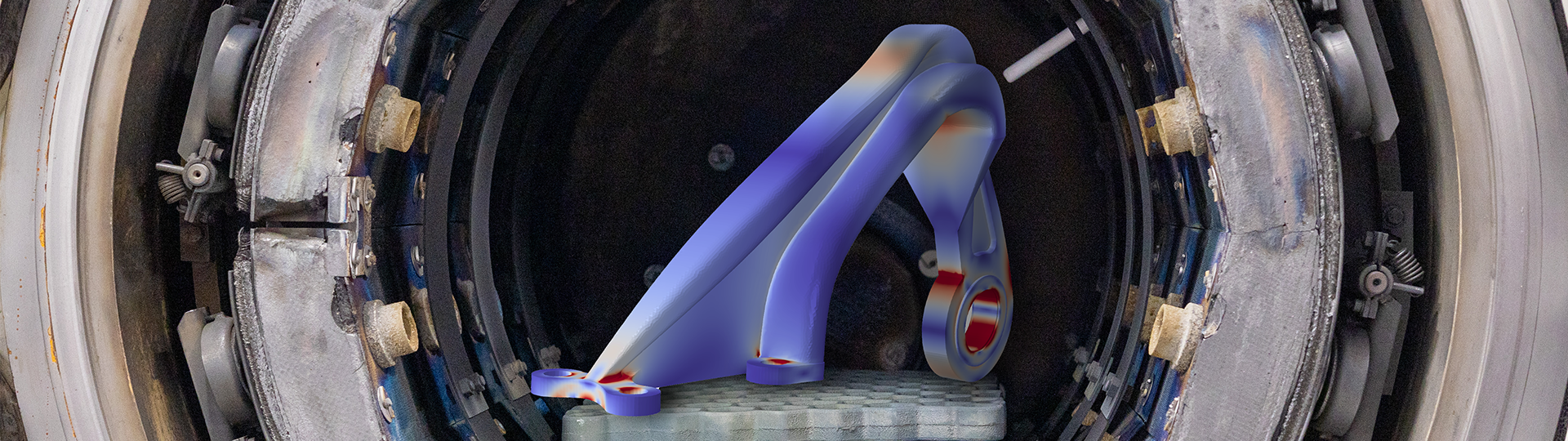

Product use simulation

- Product optimization of components, even in complex contact situations (friction, contact fatigue, etc.)

- Product optimization using virtual sensors and comparison with measurements in the field

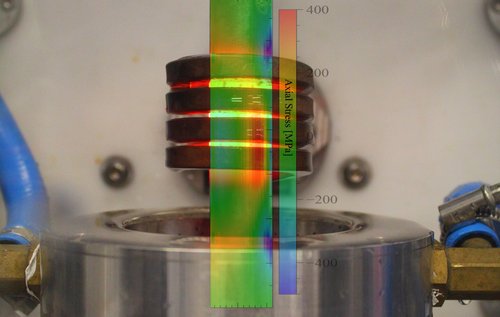

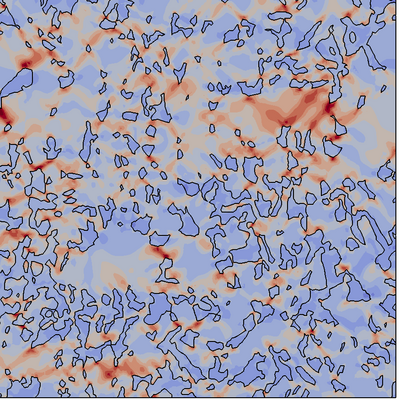

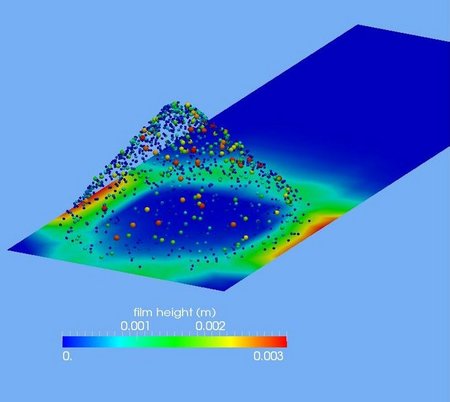

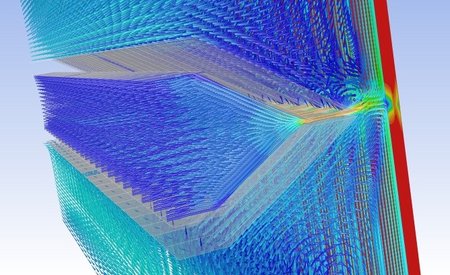

- Insight into the interior of products during manufacturing and operation

- Service life optimization and reduction of inspection intervals through increased knowledge of materials and stress

- Time-efficient product optimization and reduction of testing effort

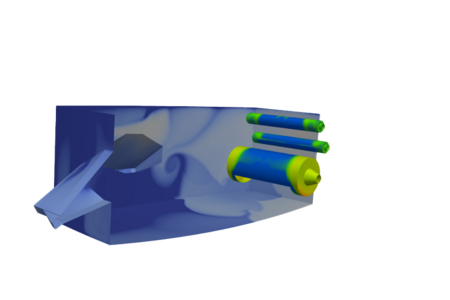

Calculation services for design and development

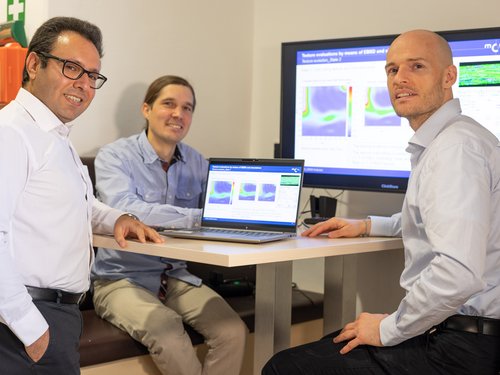

MCL is happy to support its customers in implementing their ideas in the field of component development and design.

Our main areas of focus are:

- Simple, fundamental calculation studies for a better understanding of the load situation.

- Standard-compliant design of technical components.

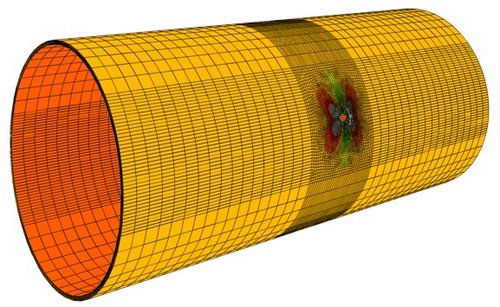

- Nonlinear calculations with complex material behavior and changing contact conditions.

MCL also offers customized tools for your simulation department for automated and user-friendly creation and evaluation for the FE software packages Abaqus, Deform, and Ansys.

Our range of services

- Stress and fracture mechanics component design Load and damage analysis

- Fatigue and endurance strength analysis

- Standard-compliant design (DIN, VDI, FKM, ASME, BS, FITNET, etc.)

- Fitness for purpose (proof of suitability for use) Damage tolerant design

- Numerical estimation of crack growth rates

- Accompanying calculations during the design phase

- Thermomechanical problems

- Die casting molds and mold frames

- Brake discs

- Furnace housings

- Electronic components

- etc.

- Complex contact problems

- Contact pressure and contact opening

- Contact fatigue

- Automation and customization of pre- and post-processing (Abaqus, Deform, and Ansys)

- Pre-built tools for customer calculations

- Scripts & plug-ins