Topographical / Morphological Surface Characterization

Focus:

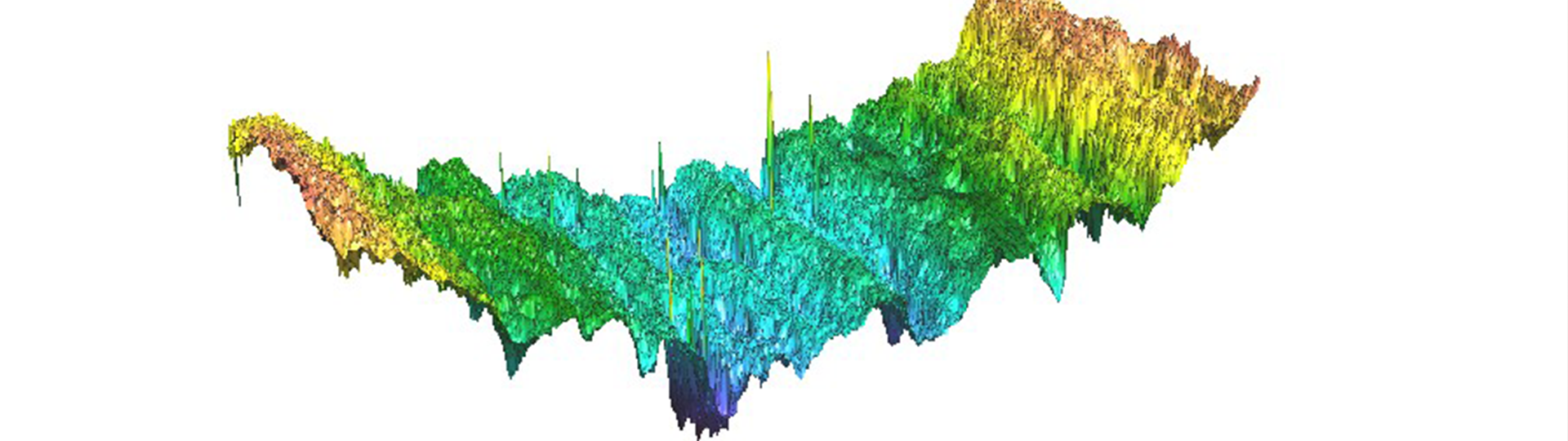

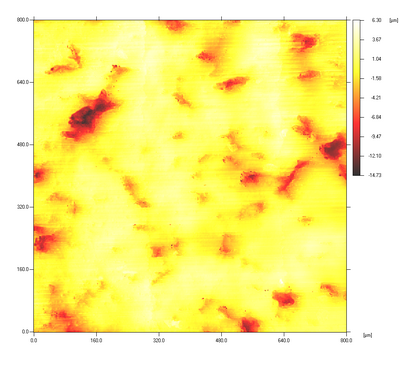

3D geometry, contour, roughness, surface structure

2D/3D topography measurements – from macro to nano

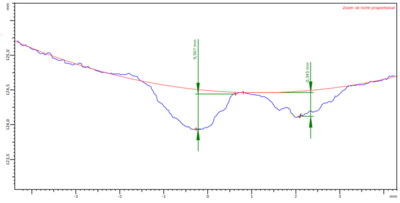

Roughness and waviness measurements

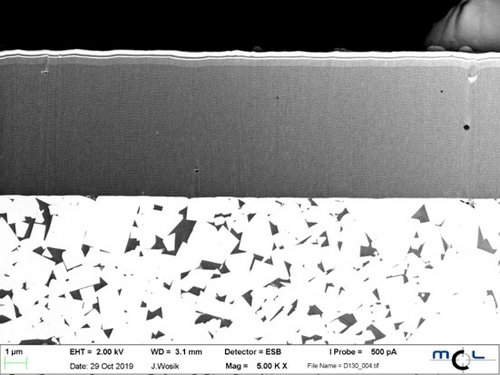

Micro- and nanostructure visualisation

Defect and surface morphology analysis

Typical methods:

AFM – Atomic Force Microscopy

3D topography at the nanometre scaleSEM – Scanning Electron Microscopy

Microstructures, surface morphologyConfocal microscopy

High-resolution 3D surface measurementsTactile roughness and contour measurement systems

Roughness, waviness, contour

Chemical Surface Analysis

Focus:

Analysis of chemical composition, bonding states, and contamination.

- Elemental and composition analysis

- Contamination and residue analysis

- Bonding state and chemical state analysis

- Phase and structural characterization

Selected methods:

- EDX/EDS (in SEM)

→ Elemental analysis (less surface-specific than XPS) - XPS – X-ray Photoelectron Spectroscopy

→ Surface chemistry, bonding states, coating thicknesses in the nanometre range - FIB-SIMS – Secondary Ion Mass Spectrometry

→ Trace elements and depth profiles - Raman spectroscopy

Chemical phases, molecular structures - XRD – X-ray Diffractometry

Phase analysis, identification of crystal structures, mixed phases, oxides, crystalline residues

Mechanical Surface Analysis

Focus:

Investigation of mechanical properties such as hardness, elasticity, friction, and wear.

- Determination of hardness and elastic modulus (micro/nano)

- Wear and friction behaviour

- Coating adhesion

- Micro-/nano-mechanics of surfaces

Typical methods:

- Nanoindentation / microindentation

→ Measurement of hardness and elastic modulus in the micro- and nanometre range - Scratch testing

→ Coating adhesion - Tribological tests (pin-on-disk, friction/wear tests)

→ Coefficients of friction, wear rates - Micro-tensile or bending tests (for thin films)

Physical Surface Properties

Focus:

Determination of functional physical surface properties.

- Electrical and magnetic properties (including local measurements)

- Thermal properties of thin surface layers

Methods:

- AFM force modes (KPFM, MFM, EFM)

→ Electrical potentials, magnetic domains - DSC of surface layers

→ Phase transitions, thermal reactions