Damage analysis for your components

Do you have a defective component/product or damaged equipment and want to know what is really behind it? We support you with in-depth damage analysis – targeted, practical, and tailored to your needs.

Whether it's fracture, cracking, wear, or thermal failure, we systematically analyze the damage, identify the causes, and support you with remedial measures if necessary. We rely on cutting-edge testing methods and many years of experience in materials engineering and damage mechanics.

Let's work together to find the cause — and the right solution.

Our services at a glance:

Analysis of component and plant damage

Systematic damage inspections of components and systems (including on-site damage assessment at the customer's premises)

Standard-compliant damage analyses in accordance with VDI 3822 procedures.

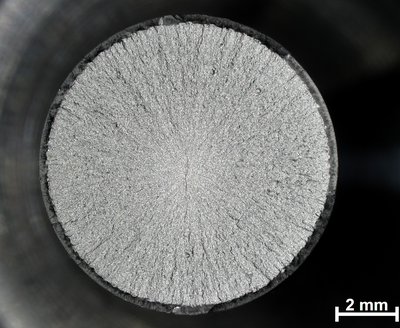

Fractographic investigations of fracture surfaces

Macroscopic and microscopic fracture surface analysis and crack origin assessments (e.g., fatigue cracks, stress corrosion cracking).

Investigations of tribologically stressed surfaces

Analysis and determination of wear mechanisms (adhesion, abrasion, surface disruption, tribochemical wear)

Simulation-based damage analyses

Component simulation to identify critical, highly stressed areas, determine material properties and their changes during operation, screen hypotheses for damage prevention

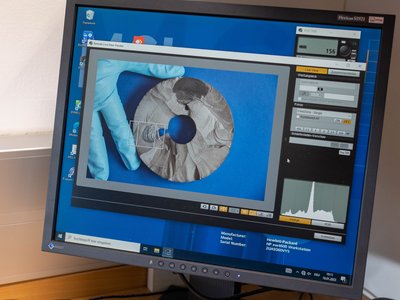

Non-destructive material defect analysis (CT, scanning acoustic microscopy)

High-resolution examination of internal structures, pores, and delaminations without destroying samples—for evaluating material defects, manufacturing deviations, and structural integrity.

Our team investigates your damage using methods such as

Mechanical stress (violent fracture, brittle fracture, fatigue or vibration fracture, rolling contact fatigue)

Tribological stress (adhesive and abrasive wear, tribocorrosive damage, surface disruption)

Thermal stress (creep, weld cracks, hot cracks, hardening cracks, distortion, etc.)

Chemical stress (general corrosion, pitting, intercrystalline corrosion)

Combined stress (stress corrosion cracking, hydrogen embrittlement, tribocorrosive damage)