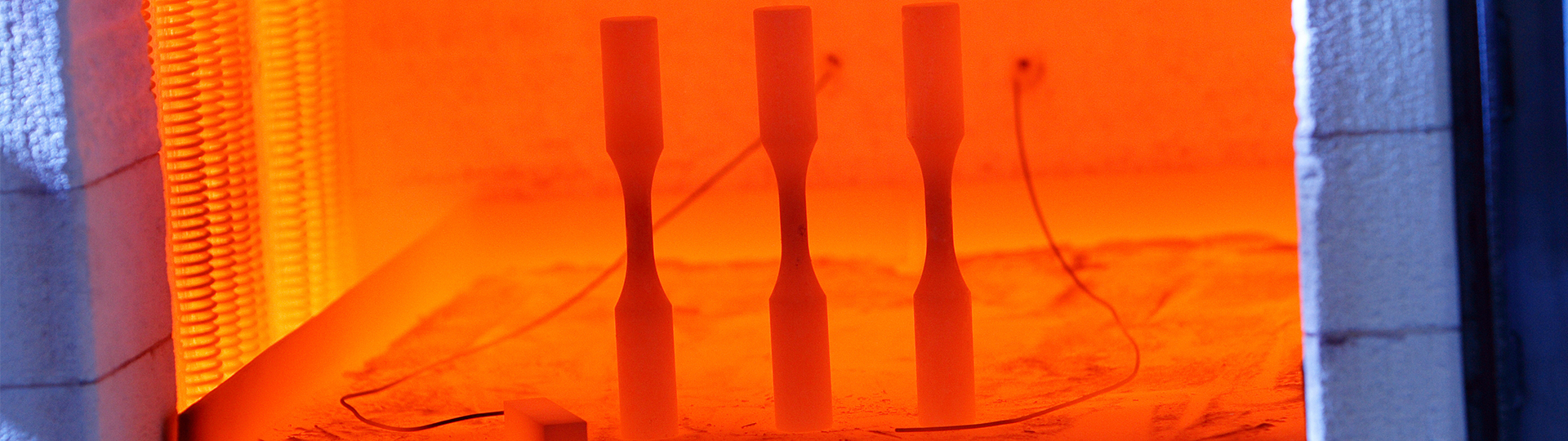

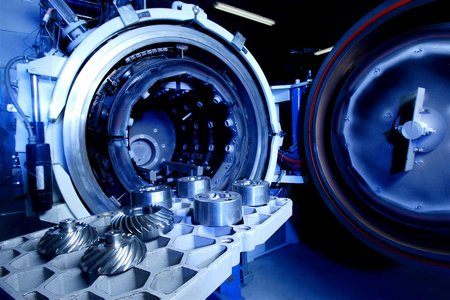

Vacuum and Protective Gas Heat Treatment

Custom, instrumented heat treatment processes under (convective) vacuum

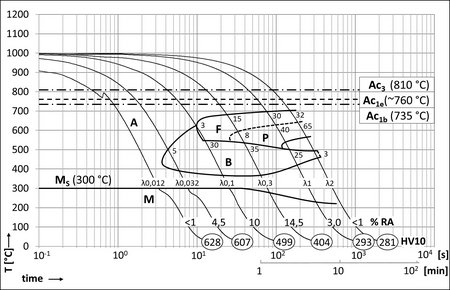

Temperature-controlled heat treatment of specimens and components including controlled quenching (l_min = 0.2)

Tempering or annealing under (convective) vacuum, protective gas (Ar, N₂), or atmospheric conditions