Modeling complex material behavior

The MCL simulation team is happy to provide ready-made material calculation routines and material model parameters for use in your simulation department, as well as performing calculations for you using advanced material models.

Material modeling based on recorded test data – for complex tests, we use inverse optimization to determine the model parameters

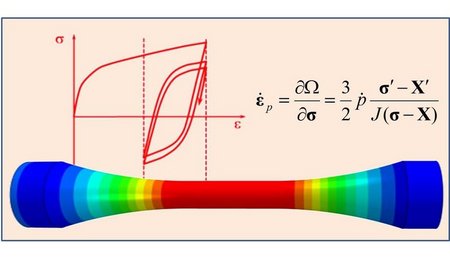

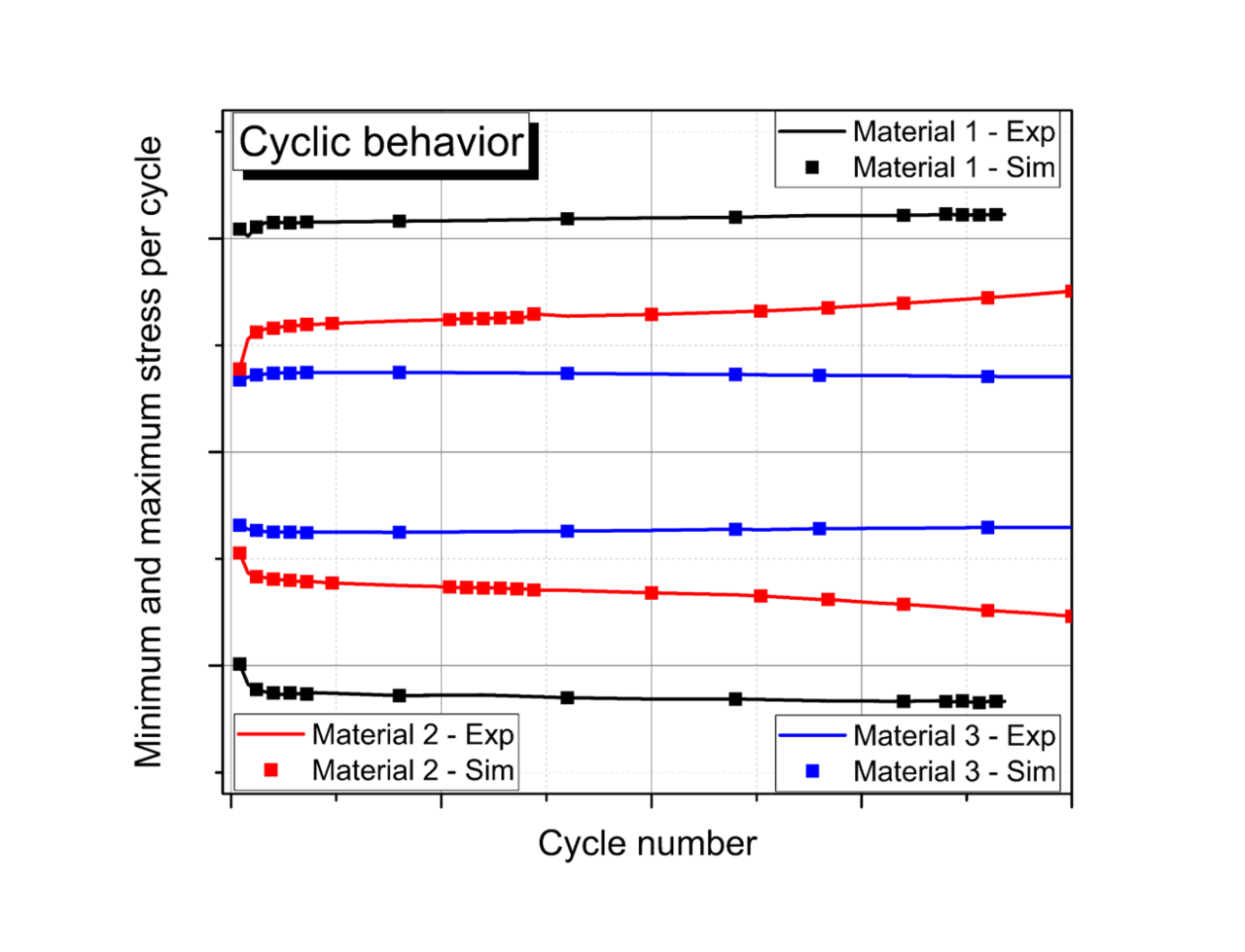

Temperature-dependent cyclic elasto-(visco)plastic material behavior:

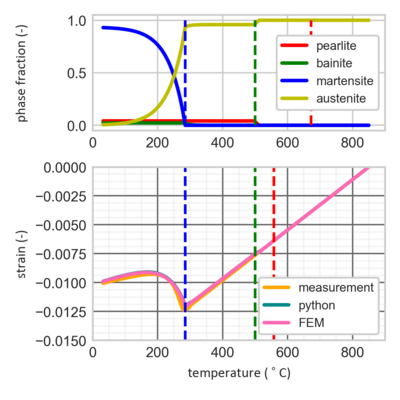

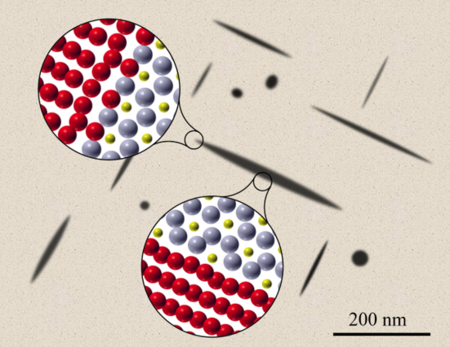

Phase transformation models, latent heat, grain growth, transformation plasticity.Development of new, customized material models

Fatigue, ductile damage, and fracture

Metallic alloys (steel, iron, copper, aluminum, titanium, nickel, etc.), ceramics, composite materials, and composite materials

Applications:

- A typical application area for nonlinear material laws is the calculation of run-in behavior due to cyclic plasticity (shakedown, build-up of residual stresses), which plays an important role in low-cycle fatigue (LCF) and thermomechanical fatigue (TMF).

- Uncoupled or coupled damage calculation and surface compaction of powder metallurgical (PM) components are further areas of application for advanced material modeling.

Material models we use to describe your material

- Isotropic and kinematic hardening

- Creep and strain rate dependence

- Chaboche model (elasto-plastic or elasto-viscoplastic)

- Damage models (e.g., Lemaitre, Hancock & Mackenzie, Gurson, Sehitoglu, etc.)

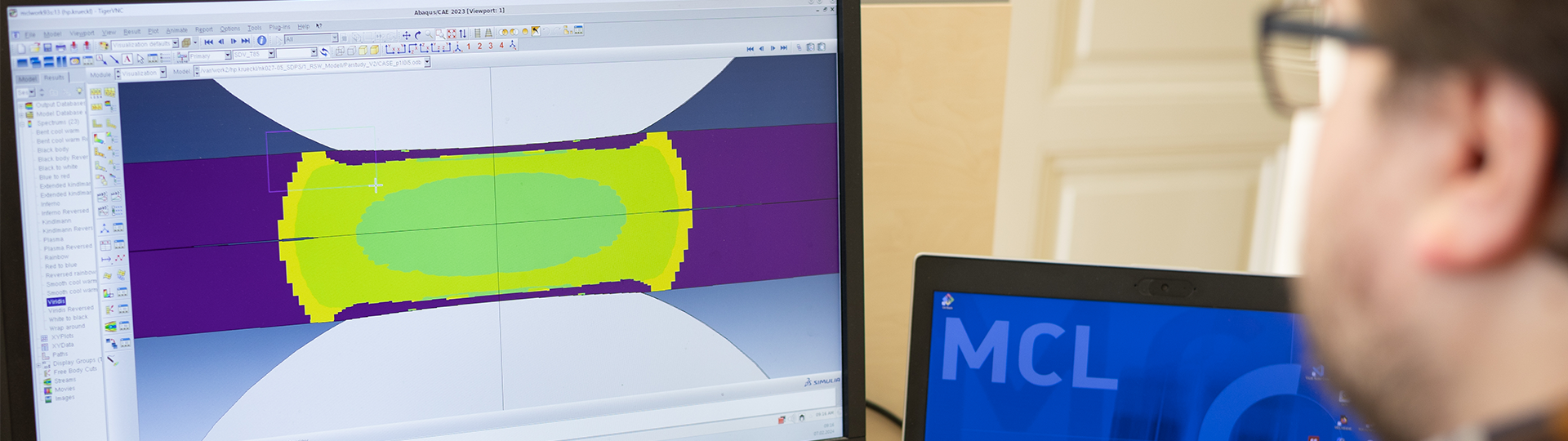

- Implementation of material models in various FE software packages (Abaqus, Ansys, Deform, etc.)

Determination of material parameters

- Test execution (tension-compression, bending, torsion, temperature, residual stresses)

- Material parameter adjustment for many material models

![[Translate to English:] Modell für die Berechnung von Korngrenzenfestigkeiten](/fileadmin/Services/user_upload/Comp_Design.jpg)