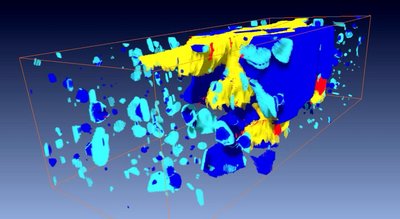

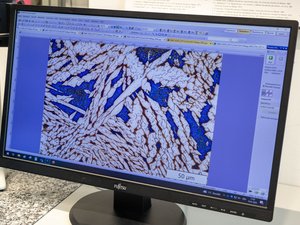

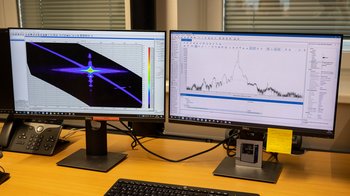

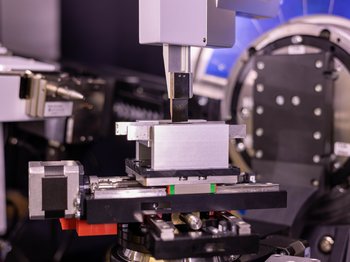

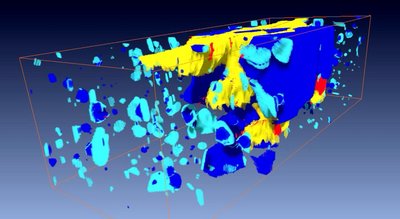

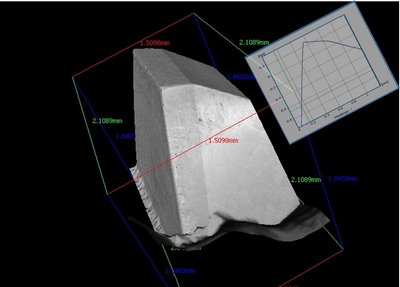

Characterization of the microstructure and microstructural composition of structural components and functional parts.

Our Focus Areas / Expertise

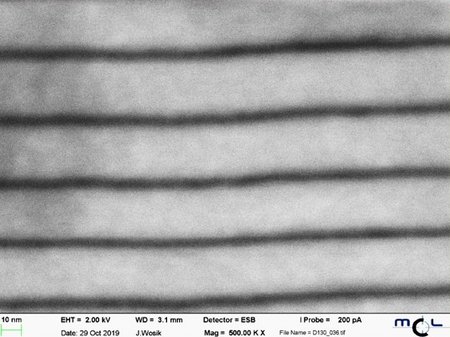

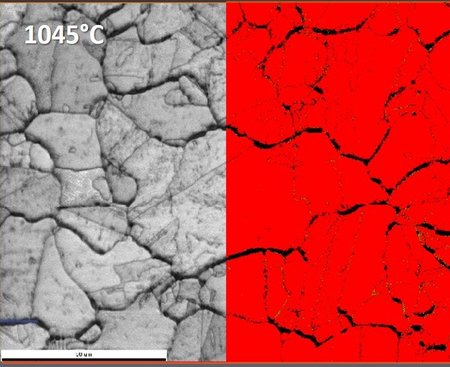

- Microstructure presentation and documentation

- Comprehensive range of etching techniques (chemical and electrochemical) for steels, non-ferrous metals, hard metals, etc.

Evaluation according to a wide variety of standards

- Cleanliness assessment according to DIN 50602, ASTM E45,

DIN EN 10247 and ISO 4967 - Assessment of carbide banding and carbide networks according to SEP 1520

- Grain size determination according to DIN EN ISO 643 and

ASTM E112 - Surface decarburization according to DIN EN ISO 3887

- Cleanliness assessment according to DIN 50602, ASTM E45,