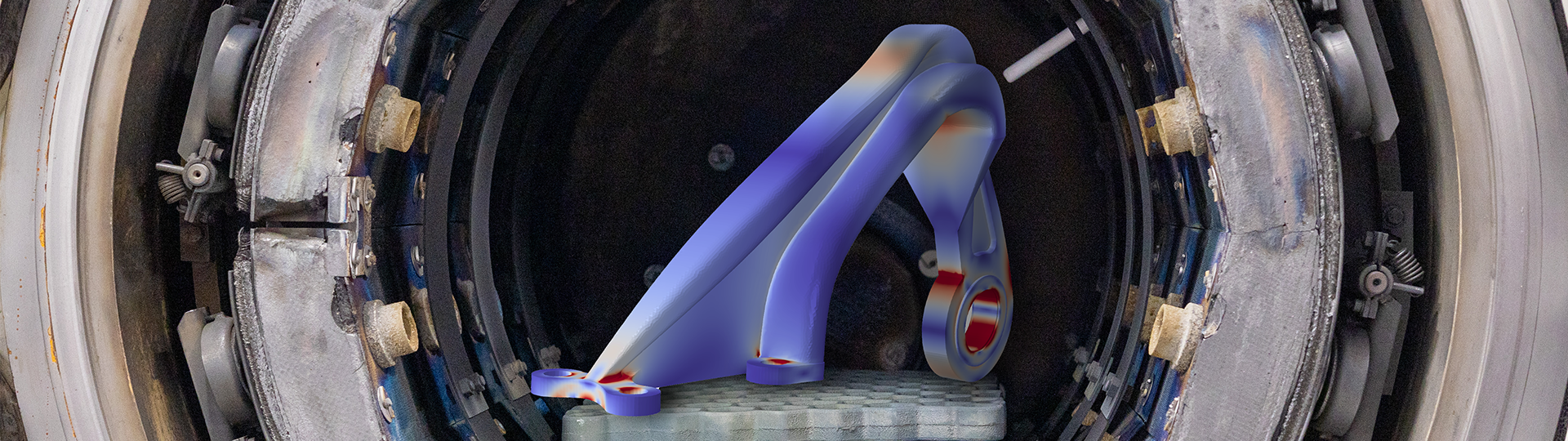

Simulation of manufacturing processes

- Development of efficient processes and process chains

- Improvement of material and component properties through optimization of the manufacturing process

- Modification of material properties through targeted heat treatment

- Improvement of the dimensional accuracy of components

MCL has been conducting research in the field of process chain simulation for many years and therefore offers the following services:

- Simulation of heat treatment and forming processes

- Stress analysis and service life extension of tools

In many cases, the manufacturing process of a component has a major impact on the behavior of the component in use.

An important goal of process chain simulation is to obtain information about changes in geometry, chemical composition, distribution of hardness, microstructure, and residual stresses, as well as any pre-damage.

We are happy to support you with FE analyses of tools and work with you to develop an optimization strategy with regard to geometry, material selection, and the parameters of the manufacturing process.

Our range of services

- Heat treatment (WBH) Microstructure and hardness distribution

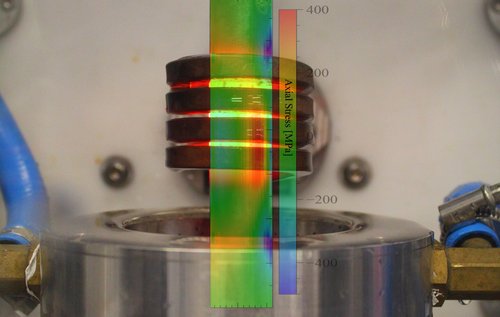

- Residual stresses

- Distortion

- Diffusion calculation Thermomechanical surface treatments (nitriding, carburizing, etc.)

- Calculation of concentration distributions

- Forming Feasibility analyses

- Pre-damage caused by forming processes

- Compaction of powder metallurgical components

- Tool loading and service life extensionForming tools

- Casting molds and mold frames

- Drills

- etc.