Friction, Wear, and Tribology Testing

Friction processes and the resulting wear often lead to malfunctions, loss of quality, or unexpected failures. Our tribological analyses help you clearly identify mechanisms, understand the fundamental tribological processes, and then specifically optimise materials and surfaces – significantly increasing the reliability and service life of your components.

Typical issues we solve for customers:

- Unexpected wear, abnormal friction behaviour, noise generation

- Corrosion, spalling, or delaminated coatings

- Contamination or process residues on functional surfaces

- Particle formation, wear debris identification, and material transfer

- Functional failures due to lubricant or coating problems

With clear results, easy-to-understand documentation, and concrete recommendations for optimisation, we help you make components more durable, processes more stable, and products more reliable.

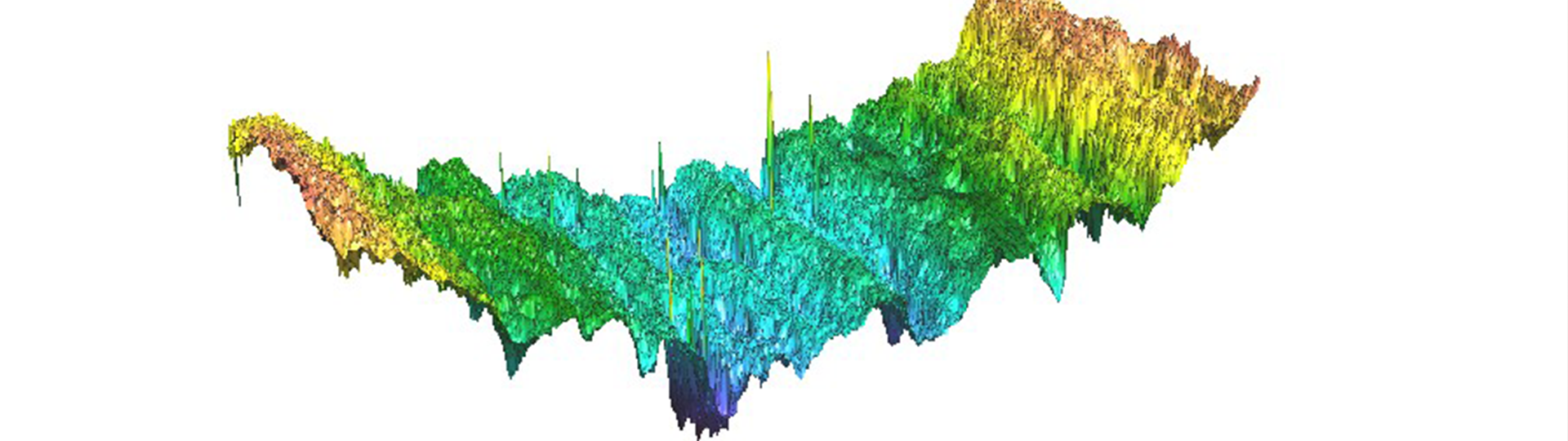

We offer professional surface analysis and tribology testing to precisely evaluate the friction and wear behaviour of your components. Using light microscopy, scanning electron microscopy (SEM), and EDX, we reliably identify wear debris, material transfer, microdefects, or coating failure. In addition, we perform tribometer tests such as pin-on-disk, scratch tests, and a wide range of other tribological tests (ring-on-disk, linear motion, component-specific tests) under realistic conditions to determine coefficients of friction, wear rates, and wear patterns with high accuracy. This gives you robust analyses, clear insights into tribological processes, and concrete recommendations for material optimisation, coating improvement, and process stabilisation.

In addition, with modern surface characterization methods (e.g. AFM, optical profilometry, XPS, XRD, Raman, ToF-SIMS), we can make underlying chemical, structural, or functional causes visible.

A service portfolio that sets the benchmark.